Free Cooling Systems

By using Free Cooling Systems, Total Thermal Operating Expenditures can be reduced up to 90%.

Free Cooling Systems, saves energy and operating expenditures in areas such as Telecommunications, Transmitting stations where traditional air conditioning applications has very high energy costs.

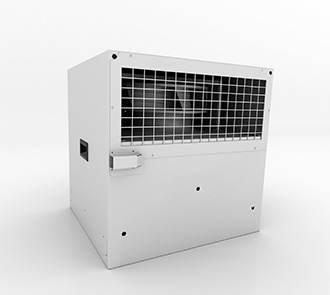

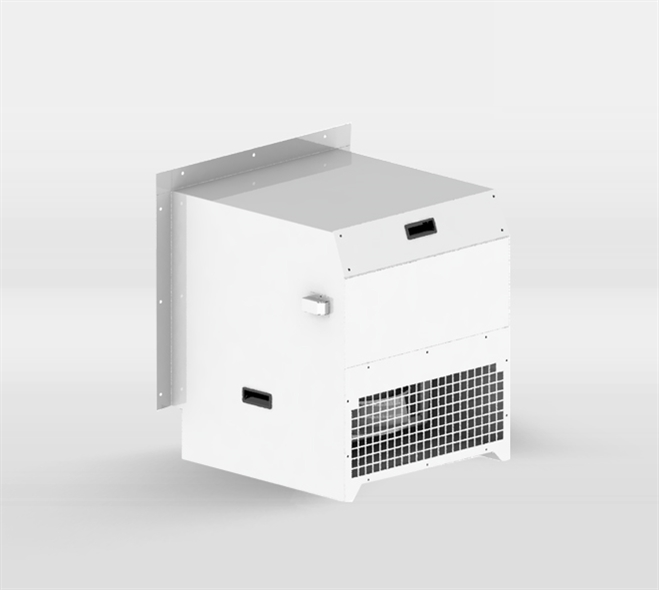

Air conditioning units in areas such as GSM Base Stations, PSTN System Rooms, Data Centers, Bank ATMs consume excessive amounts of energy for cooling.Baran Technology Free Cooling System provides maximum cooling by consuming optimum energy. The operating principle of the system is very simple. Instead of cooling the hot air, the system provides that carrying the hot air out and transfers the cold air from outside to inside by using fan. It will not let the air conditioner work as much as possible. By this way up to 90% energy saving is achieved. By using of Baran Technology Free Cooling System, the system compensates its amortization value within six months to one year depending on geographical location and climate conditions.

Technical highlights of our Free Cooling system:

Diversity and Flexibility:

Our Free Cooling system offers a wide range of applications with cooling capacities ranging from 2 kW to 8 kW (ΔT = 5°C).

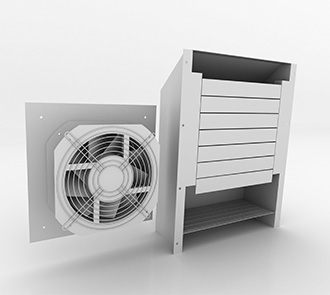

We provide Free Cooling Fanbox models with six different cooling capacities (55W-120W-190W-380W-467 and 750W).

Control Unit:

The system features a control unit capable of proportionally driving both AC (220VAC) Fans and all EC (Electronically Commutated) Fans operating in DC (48VDC). This not only enhances energy efficiency but also increases system sensitivity and flexibility.

Central Control:

Our system boasts the ability to control up to 4 Free Cooling Fanboxes with a single control unit and Mod-Bus communication port, extendable to 8 upon request. This enables high cooling capacities in large areas, simplifying system management and reducing costs.

Advanced Monitoring and Alarm Systems:

The control unit is equipped with extensive monitoring and alarm capabilities, facilitating quick detection and intervention in environmental malfunctions.

With 16 channels INPUT contact inputs, 16 channels OUTPUT dry relay contact outputs, and 16 channels ALARM dry relay contact outputs, the system sends SNMP Trap 10 Amp remotely via output channels when inputs are active. It also sends SNMP Trap in 16 different alarm situations.

Communication Protocols:

The system supports Modbus RTU TCP, UDP, SNMP(v1, v2) Trap, with a flexible structure for tracking and management through GetRequest.

It can also be managed via GUI and a web interface (embedded in the device's web monitoring screen).

Real-Time Filter Monitoring:

Real-time monitoring of filter fill levels optimizes system maintenance and prevents potential problems. We measure the fill levels of G2 and G3 Filters in real time with a digital differential pressure sensor. Zero point accuracy of the sensor: 0,1Pascal. (The filter sensor can be selected in two different structures as Analog or Digital).

User-Friendly Filter Replacement:

Our easy-to-change filter system streamlines maintenance. The G3 filter is in the form of a replaceable fiber, allowing for efficient replacement by changing only the fiber filter in the cassette when it gets dirty.

Extensible Air Conditioning Control:

The system offers the ability to control various air conditioning systems, including 2 Ductless Mini-Split Air Conditioners and 6 Direct Expansion (DX) Air Conditioners. Power consumption calculations for split air conditioners can be recorded upon request.

Data Collection:

The system reads T0, T1, T2, T3, T4, capacitive and inductive consumption information from electricity meters compatible with IEC-62056-21 protocol via RS485 bus.

It also reads power factor, total active energy, total capacitive energy, total inductive energy information from devices compatible with EASTRON SDM630 Energy Meter via the same data bus. The read values are saved in the MODBUS table.

Humidity Control:

Controlling ambient humidity levels ensures equipments protection and optimization of operating conditions. The control unit proportionally controls the EC Fan with the humidity algorithm, calculating the DEW Point value. It generates an alarm if the value is exceeded, leading to the fan's automatic stop.

Comprehensive Logging System:

Extensive parameter configuration options and event logs provide critical data improving system performance and reliability.

The system controls 67 different parameter configurations, saving 18276 Event Logs in memory, and recording 365 days of Operation Logs.

Diesel Generator Control:

Your Free Cooling system has the ability to control diesel generators for Off-Grid areas, automatically starting the generator to ensure optimal air conditioner operation and battery charging when indoor temperatures rise or DC system voltages drop to critical levels.

Heater Control:

Heater Control is done in 2 different ways. The heating method is selected from the menu on the control unit as air conditioner or external Heater Relay.

Fire Control: During a fire, the system shuts itself down very quickly. The system remains off continuously until the fire is eliminated. When the fire danger is over, the system starts to operate in normal mode again when the button on the control module is pressed.

Details

Review Models

Features

- Ability to operate at +24/-48 VDC

- Proportional Speed Control

- Ethernet Connection

- Battery Voltage Measurement

- Mains Voltage Measurement

- Instant Fan Power Measurement

- Instant Air conditioning Power Measurement

- Diesel generator control

- Ability to drive both AC and DC (EC) fan

- Real-Time Clock

- Storing data and parameters

- Analog-Digital Differential Pressure Sensor

- Operating external air-conditioning and heating unit

- Testing sensor conditions frequently during operating time

- Ability to operate air-conditioning unit/s on by-pass mode in any case of trouble

- Fan speed data is received from tacho line

- 18276 event reports about fan/air-conditioning unit for 12 months and amount of power logs consumptions can be saved in the log memory

- Menu Access requires passsword

- System prevents the noise disturbance with night mode

- When fire alarm is active , system shuts down itself

- There are USB, RS485 and Ethernet inputs for remote and local Access

- Reduction of carbon footprint

- Remote Monitoring and Control

- Send 16 different alarms as SNMP

- Low maintenance cost

- Send alarm when there is insufficient cooling and heating

- Humidity and Dew Point Control

- Reduced operating costs (OPEX)

Usage Areas

Barantech Free Cooling System is a ventilation system which also ensures system stability and helps user to decrease energy & service costs.

This exclusive system can be used in;

- Telecom System Rooms

- GSM base stations

- Radiolink stations

- Satellite Earth Stations

Free Cooling System can be applied in all type of closed cabinets.

Free Cooling System Models Table

| Model | Unit | FBX1500OB | FBX750OB | FBX750SI | FBX467OI | FBX380SI | FBX380OB | FBX190SI | FBX190OB | FBX120SI | FBX120OB | FBX120SD | FBX055SD | |

| Assembly Type | Outdoor | Outdoor | Indoor | Outdoor | Indoor | Outdoor | Indoor | Outdoor | Indoor | Outdoor | Outdoor | Indoor | ||

| Fan Voltage | Nominal | V | 230 VAC | 230 VAC | 230 VAC | 230 VAC | 48 VDC | 48 VDC | 48 VDC | 48 VDC | 48 VDC | 48 VDC | 48 VDC | 48 VDC |

| Operating Range | 200 - 277 VAC | 200 - 277 VAC | 200 - 277 VAC | 184 - 264 VAC | 36 - 57 VDC | 36 - 57 VDC | 36 - 57 VDC | 36 - 57 VDC | 36 - 52 VDC | 36 - 52 VDC | 36 - 52 VDC | 36 - 57 VDC | ||

| Control Unit Voltage | +24 / -48 VDC | +24 / -48 VDC | +24 / -48 VDC | -48 VDC | +24 / -48 VDC | +24 / -48 VDC | +24 / -48 VDC | +24 / -48 VDC | +24 / -48 VDC | +24 / -48 VDC | +24 / -48 VDC | +24 / -48 VDC | ||

| Power Consumption at Nominal Fan Voltage | W | 1500 | 755 | 755 | 472 | 385 | 385 | 195 | 195 | 125 | 125 | 125 | 60 | |

| Max. Fan Current | A | 6,6 | 3,3 | 3,3 | 10,6 | 12,7 | 10,6 | 6,15 | 6,15 | 3,55 | 3,55 | 3,55 | 2,6 | |

| Operating Temperature Range | °C | -25 / +40 | -25 / +55 | -25 / +55 | -25 / +60 | -25 / +40 | -25 / +40 | -25 / +60 | -25 / +60 | -25 / +40 | -25 / +40 | -25 / +40 | -25 / +60 | |

| Max. Air Flow | m³/h | 5920 | 4420 | 4200 | 2960 | 3100 | 3200 | 1820 | 1930 | 1500 | 1590 | 1700 | 1090 | |

| cfm | 3480 | 2600 | 2470 | 1740 | 1820 | 1880 | 1070 | 1140 | 880 | 940 | 1000 | 640 | ||

| Cooling Capacity | W / K | 2020 | 1510 | 1440 | 1010 | 1060 | 1090 | 620 | 660 | 510 | 540 | 580 | 370 | |

| ΔT = 2.5°C | kW | 5,1 | 3,8 | 3,6 | 2,5 | 2,7 | 2,7 | 1,6 | 1,7 | 1,3 | 1,4 | 1,5 | 0,9 | |

| ΔT = 5°C | 10,1 | 7,6 | 7,2 | 5,1 | 5,3 | 5,5 | 3,1 | 3,3 | 2,6 | 2,7 | 2,9 | 1,9 | ||

| ΔT = 7°C | 14,2 | 10,6 | 10,1 | 7,1 | 7,4 | 7,7 | 4,4 | 4,6 | 3,6 | 3,8 | 4,1 | 2,6 | ||

| ΔT = 10°C | 20,2 | 15,1 | 14,4 | 10,1 | 10,6 | 10,9 | 6,2 | 6,6 | 5,1 | 5,4 | 5,8 | 3,7 | ||

| Filter | Class | G2 - G3 | G2 - G3 | G2 - G3 | G2 - G3 | G2 - G3 | G2 - G3 | G2 - G3 | G2 - G3 | G2 - G3 | G2 - G3 | G4 | G4 | |

| Filter Area | m² | 1,3 | 1,20 | 1,20 | 1,00 | 1,00 | 1,00 | 0,75 | 0,75 | 0,75 | 0,75 | 0,50 | 0,50 | |

| Fan Box | Width | mm | 720 | 720 | 655 | 635 | 635 | 640 | 635 | 640 | 550 | 550 | 455 | 250 |

| Height | 915 | 790 | 970 | 655 | 860 | 640 | 860 | 640 | 735 | 550 | 455 | 250 | ||

| Depth | 690 | 690 | 665 | 610 | 610 | 630 | 610 | 630 | 515 | 530 | 195 | 80 | ||

| Air Inlet Cover | Width | mm | 740 | 740 | 620 | 635 | 590 | 635 | 490 | 550 | 490 | 550 | 400 | 400 |

| Height | 490 | 490 | 200 | 655 | 200 | 655 | 195 | 550 | 195 | 550 | 595 | 595 | ||

| Depth | 495 | 495 | 260 | 610 | 255 | 610 | 260 | 530 | 260 | 530 | 140 | 140 | ||

| Exhaust Cover / Motorized Damper | Width | mm | 620 | 400 | 355 | 400 | 300 | 340 | 300 | 340 | 410 | 330 | ||

| Height | 355 | 395 | 355 | 395 | 300 | 340 | 300 | 340 | 600 | 450 | ||||

| Depth | 260 | 245 | 260 | 245 | 260 | 210 | 260 | 210 | 220 | 135 | ||||

| Weight | Fan Box | kg | 69 | 54 | 59 | 43 | 51 | 43 | 51 | 43 | 45 | 35 | 21 | 2 |

| Air Inlet | 18 | 18 | 13 | 0 | 12 | 0 | 11 | 0 | 11 | 0 | 6 | 6 | ||

| Air Outlet | 18 | 8 | 13 | 8 | 11 | 6 | 11 | 6 | 6 | 4 | ||||

| Fastening Feet | 7 | 7 | 4 | 0 | 4 | 0 | 4 | 0 | 4 | 0 | 0 | 0 | ||

| Total | 94 | 79 | 94 | 51 | 80 | 51 | 77 | 49 | 71 | 41 | 33 | 12 | ||

| Sound Level (Max. rpm) | dB(A) | 80 | 72 | 72 | 65 | 65 | 65 | 60 | 60 | 60 | 60 | 60 | 60 | |

| Protection | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | ||

| Attention: The informations in this document are subject to change without notice. | ||||||||||||||

)

)

)

)

)